Have you found yourself asking “What is the best foam to use for sofa cushions?” Whether you’re a consumer looking to purchase a sofa or chair or you’re a just out of school designer, today’s post will share with you the differences between good, better and best upholstery filling materials. You’ll know exactly what to ask for to get the comfort level that’s just right for you, or your clients. Plus an understanding of the sustainability aspects of your choices.

The Best Foam to Use for Sofa Cushions

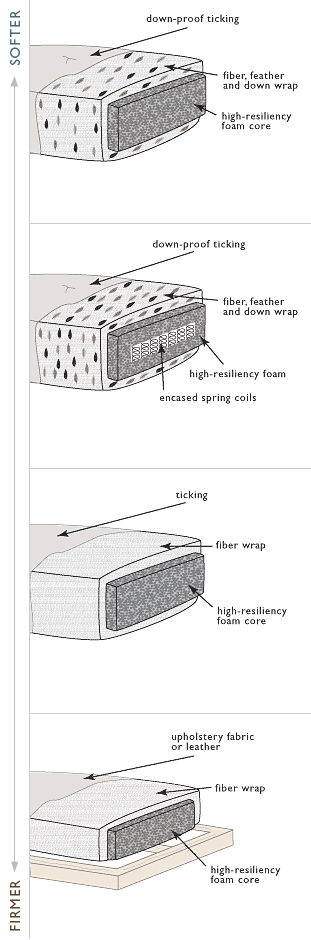

Let’s start by looking at foam-based interior cushion construction. Depending on whether you like a firm seat or a soft seat, the graphic below shows you what some of your options could be. You’ll see a continuum, of some of the types of options that are available, from the firmest on the bottom to the softest foam seat construction option, on top.

What is Foam?

Foam has two properties that are important to consider: density and firmness. These can both be tailored to your exact specifications so you get the comfort level you want.

Foam density is a specific measurement of how much weight, in pounds, polyurethane foam can handle per cubic foot. This density rating tells you the strength of the foam. The higher the number, the longer the foam will last. It should not be used exclusively as a sign of durability or comfort, because firmness and lifespan of foam products like mattresses and cushions, depend on many factors, including density.

ILD or IFD is a firmness measurement which tells you how hard or soft a foam is. The higher the number, the firmer the foam. This number also represents how many pounds the foam will hold before it collapses. If you take a block of foam that is a 12″ x 12″ x 12″ cube, after a certain ILD is reached, that foam will collapse.

Low density foam is the lowest quality filling material for cushions. These cushions have a shorter life span and may leave your sofa looking like it is about to collapse after just a few years.

Polyurethane Foam Cushions

Polyurethane foam is a by-product of the same process used to make petroleum from crude oil. It consists mainly of two chemicals: polyols and isocyanates. When these chemicals are mixed together and baked in special chambers, they rise, exactly like a loaf of bread does, and form the substance we know as foam. Polyurethane cushions are affordable and long lasting. Poly-foam is pliable and easily formed into whatever shape you might need.

Soy-Based Foam

If you want an eco-friendly alternative to polyurethane try soy based foam. These foam cushions are a combination of Soy(from the soybean) and polyurethane. Many manufacturers offer soy based polyols, but only a few manufacturers use a foam that has a high proportion of a soy as compared to the oil based polyol. The soy foam cushion is comfortable, sturdy and resilient.

Latex Based Sofa Cushions

Latex comes from Rubber trees which makes it biodgradeable and resistant to mold and mildew. It’s heaver than other foam materials and has a firm cushion core. You can wrap the latex cushion with a down/feather combination for a softer cushion. Latex foam is more expensive than polyurethane and soy based foam. It will maintain it’s shape for the life of your sofa (approx. 20 years), but cushion styles are somewhat limited because they don’t have the curves and tufting that is available with standard foam.

Down/Feather Cushions

Down/feather cushions are an extravagance as compared to other foam cushions. These cushions are so soft and plush that you sink into them when you sit down and you might find it a bit difficult to get out of once you plop down! Down cushions must be fluffed and turned regularly to maintain their shape and extend their life. If you love the rumpled, not too perfect look than these cushions are for you!

Cotton Cushions

Cotton is 100% plant based and believe it or not it makes a firm cushion! Cotton cushions have been used in outdoor furniture for years because of it’s comfort and affordability. You should treat the cushions with a protectant to prevent fading and mold. Cotton cushions will get matted down and lumpy over time.

Sustainable Foam Cushion Manufacturers

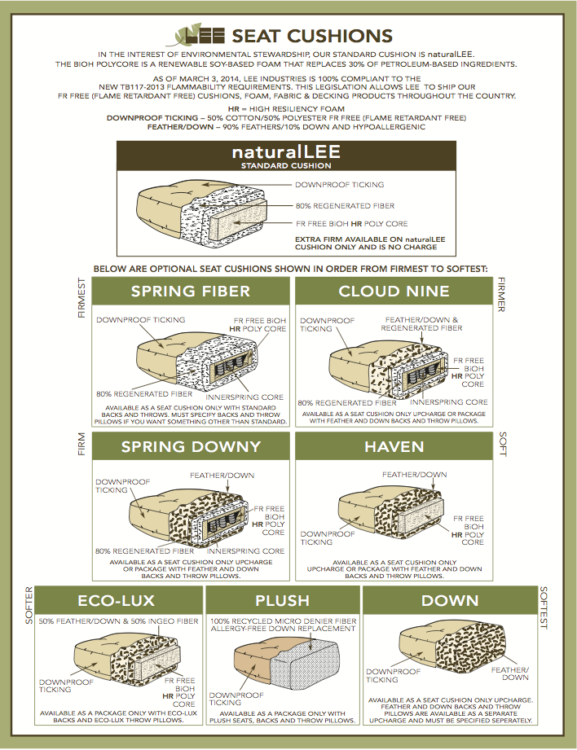

The manufacturer in the furniture industry constructing their STANDARD seat cushions with 30% soy based polyols in their foam seat cushion right now is Lee Industries. Here’s a chart from their website so you can see and understand your options.

There are other upholstery manufacturers, like Harden Furniture, Century Furniture, Cisco Brothers and more who have also long championed real sustainable cushion and/or frame construction, but since today’s post is on cushion filling materials, I’ve chosen to call out Lee, who has been the leader for a long time in using foam with the highest percentage of this soy based polyol in their foam cushions.

Lee is also a leader in meeting the new law banning the use of flame retardants in foam. For more information on why flame retardants were just recently banned in foam, see this article in the Huffington Post. Please make sure to ask, if you’re buying or specifying foam, to ask for foam made without flame retardants.

Two very small manufacturers making extremely environmentally friendly sofas to the highest environmental standards, and who will customize, are EcoBalanza in Seattle and Bean Products in Chicago.

Going back to foam, please take a look, carefully, at this picture: It looks pretty, at first glance, right? But what do you see when you look at those cushions a bit more closely?

Save and buy the very finest seat and interior construction once, and you won’t be sorry! You can find the finest overall interior sofa construction from companies like E.J. Victor, Tomlinson Lambeth, Century Furniture, Hickory Chair, Thayer Coggin and, headquartered in the UK, George Smith Furniture is the touchstone.

This home in Athens, GA is furnished with George Smith upholstery.

The picture below is from one of Century Furniture. You can watch their educational and beautifully executed video series about how their furniture is made, constructed and finished by clicking here.

Companies like Century are able to secure and use any interior filling that you would like to specify, and can execute any type of custom upholstery, but, keep in mind, that could change the warranty if they’re not as familiar with the performance characteristics as what they have already in their line.

Has today’s post helped you? If it has, please let us know in the comments and please, if you have additional questions about how fine upholstery is made, also leave those in the comments so that we can answer them for you.